Item B below tries to provide understandable description of our water intake, treatment and distribution system.

This is a companion piece to the previous edition about how our Waste Water Processing Works.

But first …. an update about our new gWorks Billing System

A. March 10th Billing

The March 10th billing will be the first one done by gWorks. We will be watching it closely. It’s very likely that we could miss things, so please look at your bills carefully!! If you see any issues or have any questions or concerns please reach out to Teri (archcapebilling@gmailcom).

For the March 10th billing, ALL statements will be sent by mail (just to be safe). The Sanitary and Water bills will arrive in the same envelop, and not a post card.

From then on:

- To ONLY get your statements by mail, don’t create a gWorks account.

- To ONLY get your statements by email, create a gWorks account

- To get your statements by email AND mail, create a gWorks account, select ‘My Account’ on the left side of the page. Under ‘Notification Preferences’ click on ‘Edit’. For ‘Receive Utility Paper Bill’ toggle the button so that it is bright orange.

For information about setting up a gWorks account, Autopay and more click here.

B. Our Water Intake, Treatment and Distribution System

This article describes, in simple terms, the Water District’s intake, treatment and distribution system and the rejuvenation work that is being done or needs to be done. The intent is to foster appreciation for the sophistication of the system and an understanding of how ratepayer money and the time of Matt Gardner and his team of District personnel and contractors are being spent. The footnotes(1-5) refer to steps being taken or needing to be taken to rejuvenate the system.

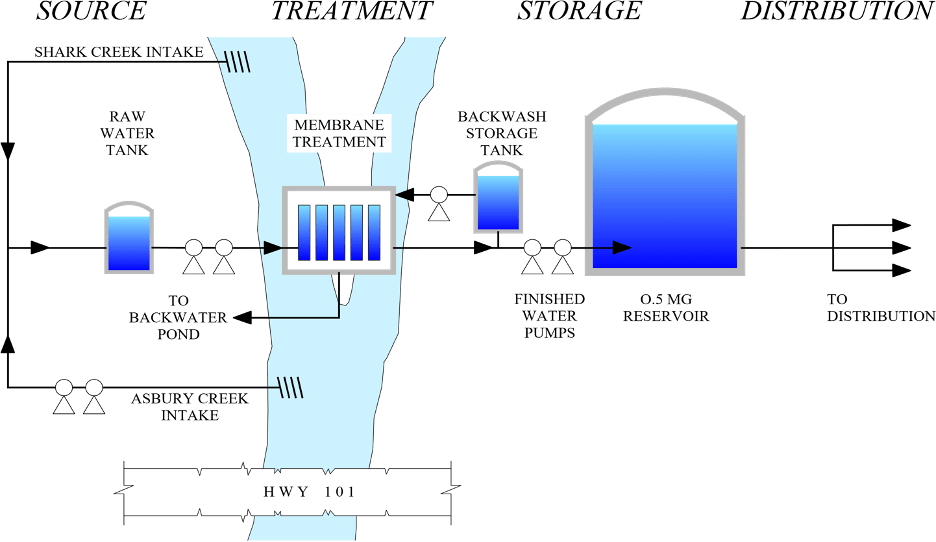

How the System Works (You can follow the flow using the picture below)

Our water treatment plant which is located at the eastern end of Shark Creek Lane is an Ultrafiltration (UF) Membrane System. From a 10,000 ft level, it is a water purification process that combines membrane filtration (that separates out raw water from clean water) and Sodium Hypochlorite (that kills bacteria and virus microorganisms).

The source of our water is two creeks, Asbury Creek and Shark Creek, that wind through the hills and Watershed to the east of Arch Cape. The Water District has a permit from the State that sets the limit, in gallons/minute, of how much we are allowed to take from each creek.

Shark Creek is the eastern-most creek, which is used most of the year. Shark Creek flows through our Watershed and over a small collection pond with a dam that is east of the water plant. The dam diverts a permitted amount water to a Raw Water Tank at our treatment plant. No pumping is needed, it flows with gravity. Sediment is removed from the collection pond every year so it maintains an adequate volume of water.

Asbury Creek is the western-most creek, which is used during the summer months. The permitted amount of water is captured directly out of the creek from an intake point just east of 101 by Shark Creek Lane and is pumped (1) up to the Raw Water Tank at the Water Plant.

Pumps at the Raw Water Tank, forced the raw water through a series of .02 micron membranes (filters). This ultrafiltration process filters out all large particles, all bacteria, and most viruses, from the water. Suspended particles that are too large to pass through the membrane stick to the outer membrane surface and fall to the base of the basin where they are flushed out to the backwash pond. The infusion of Hypochlorite (a chlorine-based bleach) (2) kills any potentially remaining bacteria, viruses, and other microorganisms that might pass through. Fresh water and dissolved minerals then pass through the member to the clean water side.

On its way to the water storage reservoir, some of the clean water is stored in a Backwater Storage Tank. This water is later used to “backwash” the membranes. Backwashing is the pumping of clean water from the Backwater Tank back through the clean water side of the membranes to push out any particles that may be stuck in the filters so that they fall onto the raw water side of the membranes and drained out to the backwash pond (3).

The clean water that doesn’t go into the Backwater Tank is pumped up into the 500,000 gallon Water Reservoir.

The distribution part of the system brings the clean drinking water to community. Using gravity as the pressure source, the clean water in the Reservoir is distributed to all the homes in Arch Cape via two water mains and a series of distribution lines that eventually end at water meters at each home. Placed within these water mains and distribution lines are a series of valves(4) which allow sections of the lines to be isolated, so that a leak in one pipe can be shut off without interrupting service to the remaining residents. Fire hydrants, air release systems, and blow off mechanisms for flushing are also embedded in these lines. At the end of the lines are the water meters that mark the dividing line between the District’s water system and the homeowner’s private drinking water system and they track actual usage by the home.

The process of making water is computer controlled and monitored(5) and Matt has ultimate control over determining when water needs to be made and when the membranes need to be backwashed.

Steps being taken / needing to be taken to Rejuvenate the System

*1 – Asbury Creek:

a. 2nd Asbury Creek Pump: The District’s water intake system was designed and built with two pumps in Asbury Creek to provide redundancy in case one failed. A number of years ago one of the pumps failed and was not replaced until Matt did it last year.

b. Replacement of Intake: The State is requiring the District to move the water intake 200 feet upstream so that the State can do work in the creek to encourage fish passage. The State’s work will require a bridge to be built over 101 and a new District water main. To meet the State’s requirements for this project, the District will have to do over $500,000 of work and about $150,000 of it will NOT be reimbursed by the State. For more on this project click here.

*2 – Water Plant Corrosion: The Water Plant facility was built with fans to vent the marine air and the Hypochlorite gas, as both of these elements are corrosive to metal components in mechanical valves, electrical circuits, etc. However, the fans have never been run and, as such, they themselves started to corrode along with critical components of the plant and its equipment. When a valve would begin to corrode, rather than replacing it, the corroded value would be switched with another valve in the plant that is less corroded.

Matt and his team have tested all fans and worked with the electrician to have them run automatically. An additional fan has been installed at floor level to remove chlorine gas as it is heavier than air and another has been installed in the computer control room, along with a dehumidifier, to minimize the impact of corrosion on the computer systems and electronics. Repair of the critical circuity in the fuse panel will be repaired later this fiscal year or early next fiscal year as budget allows.

Additionally, 4 of the most corroded valves have been replaced with brand new ones, and the others will be replaced on a periodic cycle.

All componentry, pipes and fittings have been wire-brushed to remove all corrosion and restored to new like condition.

*3 – Maintenance of Backwash Pond: This pond collects all the sediment that washes off of the filters as part of the water treatment process. For almost a decade, this pond has never been drained and cleaned properly and became overfull of mud and sediment and organics etc.

Last month Matt and Troy manually pumped all the contents into a collection bin and hauling it to the plant to run through the treatment process so as not to make any environmental impact dumping it or having it dumped. The remaining contents of the pond was shoveled out and the basin was washed down until it was clean. Periodic cleaning of the pond is now part of the normal maintenance cycle.

*4 – Verification of Distribution Valves: Matt and his team have now identified the location of all 93 valves across the District and tested them. 10 were discovered to not be functional and require immediate attention. They will be replaced this year and next as budget allows.

*5 – Updating of Supervisory Control and Data Acquisition (SCADA) system: SCADA is the name of the computer electronics that control and monitor the functioning of the entire process at the Water Plant. The primary control-interface panel broke over four years ago and was not replaced. The remaining computer (Windows 7) reached the end of its life cycle several years ago and periodically crashes. Vendor software licensing is out of date. The software currently running does not comply with state requirements.

In November, Matt, his team, the acting District Administrator and a Board member were involved in replacing and upgrading the SCADA system with current software, licensing, and technology so that the designed redundancy is built back into the system. The control function has been secured behind the recently installed firewall so as to minimize the risk of being hacked.