There have been questions about how our water and waste water systems work and exactly what is Matt needing to do to rejuvenate them. Its tough to give meaningful answers to these questions without setting some context. The below (item B) tries to provide understandable context that will answer questions about our waste water system (and there is a really cool picture). Next month we will do the same for the water system.

But first …. an important notice about our new Billing System

A. We have a new Billing System called gWorks – check out the Districts’ web site

Both Districts have just been migrated over to a new billing system. A company named gWorks purchased UB Max, the system that we have been using, and gWorks has now phased out the UB Max system and replaced it with their own. We had asked for a bit of notice before the final migration so we could check things out, but alas…

Please go to the District Web Site for essential information about the gWorks Billing System and what you need to do if you want to activate/set up an online gWorks account to request emailed statements or set up auto pay. Click here

If you see any issues on your online gWorks account, or on the upcoming March 10th billing or have any questions or concerns please reach out to Teri (archcapebilling@gmailcom). She will get back to each of you as quickly as she can. Matt is focused on managing plant and operations, so Teri is now the point person on this.

B. Our Waste Water Processing System

This article describes, in simple terms, the Sanitary District’s wastewater processing system and the rejuvenation work that is being done or needs to be done. The intent is to foster appreciation for the sophistication of the system and an understanding of how ratepayer money and the time of Matt Gardner and his team of District personnel and contractors are being spent. The superscripts/ footnotes(1-9) refer to steps being taken or needing to be taken to rejuvenate the system.

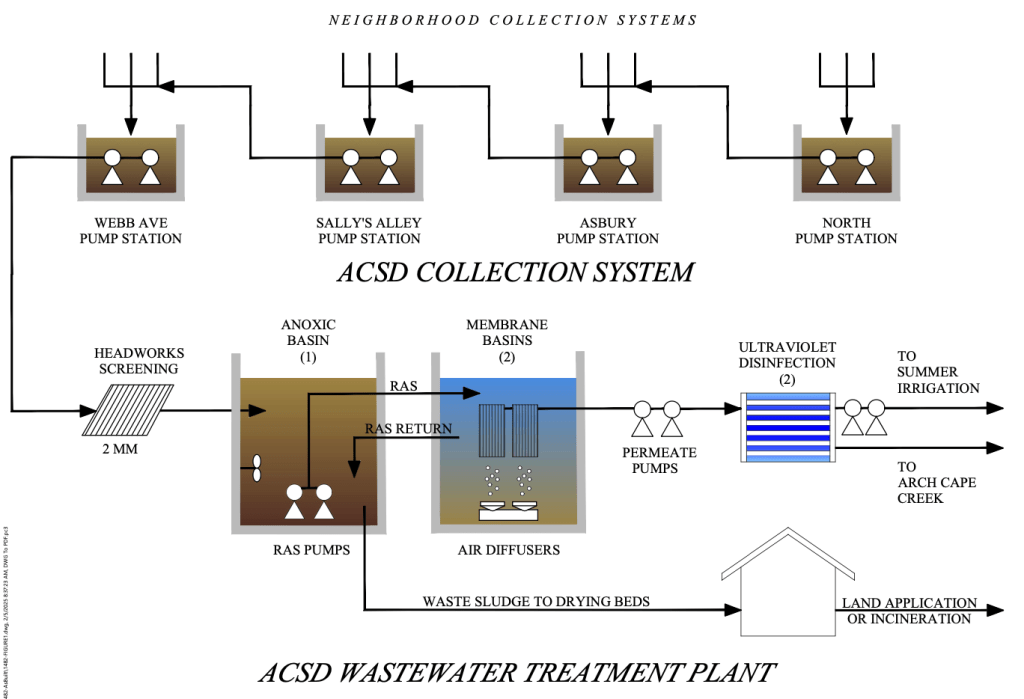

How the system works (you can follow the flow using the picture below)

Our wastewater treatment plant is called an Activated Sludge Membrane Bioreactor (MBR) . From a 10,000 ft level, it combines biological treatment (using microorganisms to break down organic matter) with membrane filtration (separating out the treated water) and ultraviolet technology (killing any remaining bacteria and virus microorganisms).

From your house to the treatment plant on Shingle Mill Lane, the wastewater collection system takes a circuitous route through a number of sewer pipes1 and, depending upon where you live, up to four sequential pumping stations. Each pump station pumps it to a higher elevation where it flows to the next pump station via gravity until it reaches the final pump station (Webb Lift Station) on Shingle Mill.2. All wastewater across the district goes through this final pump station which pumps it all to the sanitary plant through a pressure main.

This pressure main from the Webb Lift Station ends at the “Headworks” where the wastewater goes through a screen3 to remove plastics, hygiene products, rags, sticks and other large objects. The remaining raw sewage flows into a large basin called the “Anoxic Zone”. A Mixer4 in the Anoxic Zone blends the raw sewage with activated sludge that has been returned from the membrane filters (see next step) and with the right amount of microorganisms (managed and balanced by Staff) to create an active treatment environment.

This raw sewage now combined with the returned activated sludge (RAS) is then pumped5 into the Membrane Bioreactors (MBRs 1 & 2) where it is infused with the right amount of air to complete the biological treatment. This infusion of sludge with oxygen is called “Mixed Liquor”. The high oxygen level supports the growth of microorganisms and other beneficial bacteria within the sludge which then breaks down and metabolizes the organic pollutants (like food, oils, and waste) into simpler substances like carbon dioxide, water, and new biomass.

The next step is membrane filtration. Two large pumps pull the mixed liquor through a set of 0.4 micron filters (membranes6&7) in order to separate out the finished water (effluent). This Microfiltration process keep solids, all bacteria, and some viruses on one side of the membranes while drawing the “clean” treated water through the filter to the other side. The filtered water (permeate) then flows around Ultraviolet (UV) light bulbs8 that inactivate any remaining organisms.

The finished water is discharged into Arch Cape Creek in winter or reused as irrigation on Sanitary District property reserved for this purpose in the summer. The sludge separated by the MBR filters flows back into the Anoxic Zone as the return activated sludge to start the process over again. Some biosolids go through the process again and some are wasted into sludge drying beds. Once dried, the biosolids are either spread across District property reserved for this purpose or shipped off to an incinerator in Seaside.

This process, which is computer controlled and monitored9, is never ending.

Steps that are being taken / needing to be taken to Rejuvenate the System

*1 – Sewer Pipes: The sewer pipes themselves, with no maintenance or replacement over the past 8-10 years, have become old, cracked and otherwise damaged. This allows volumes of rainwater and sediment material to find its way into the sewer pipes, through the pump stations and into the sanitary plant. Processing this additional volume decreases the capacity of the treatment system. For every 30,000 to 40,000 gallons of water that are used by the community, more than 300,000 gallons are processed by the wastewater plant during heavy rainfall events.

*2 – Webb Lift Station: The Webb Lift Station reached the end of its useful life 6-7 years ago, and has been subject to constant problems and failures. The current Sanitary Board, along with Matt Gardner and Curt McLeod, our professional engineer, made its replacement a priority. The District has secured funding from a FEMA grant that is paying 90% of the $575,000 cost to replace the lift station. From beginning to end, the lift station will be built from the ground up in less than 6 months and the project will be complete by this spring.

*3 – Headworks Screening: The screening has aged to the point that it is no longer working adequately as it allows foreign materials (feminine products, zip ties, dental floss, hair, random plastics etc.) to make their way through. As a result, in a later state of the process, this material lodges itself in between the Membrane filters, ripping some of the filter fibers which lowers the quality of the effluent that is produced and reduces the life of the membranes. Replacement of the screening equipment is a high priority for the District.

*4 – Anoxic Zone Mixer: Over the past 7-8 years of operation the current mixer has periodically failed. A new mixer was purchased 6 years ago, but wasn’t installed and has been sitting in offsite storage. In December, Matt and his team pulled the mixer out of storage and successfully installed it.

*5 – Return Activated Sludge Pump Check Valves: The check valves have been clogging and slowly rusting apart. This malfunctioning has caused the pumping efficiency to drop by 50%, from 800 gallons per minute (24×7) to 400 gallons per minute. A new check valve system costs $3,300. Alternatively, Matt and his team rebuilt one of systems at a cost of $1,200. The second rebuild kit for the second valve has been ordered and will be installed this spring.

*6 – Membranes: There are two sets of Membrane Bioreactors (MBR) both of which have recently been fully drained and physically cleaned. Between the two of them, about 4,000 gallons of grit and old sludge have been manually removed. These membranes have been in service for nearly six years. Replacement is likely to be needed within the next two – three years given our less than desirable Headworks screening system described above (#3). With new Headworks screening equipment, the membranes can work efficiently for potentially 10 to 12 years before replacement.

*7 – Membrane Filters: 800 of the 3,600 filters in MBR 1 have been individually cleaned and inspected in order to understand how well they’re performing. The diagnostics have revealed:

- Clogging of the air diffusers below the filters likely due to value failures.

- Torn and damaged filters. The foreign materials, passing through the prescreening system in the Headworks (described in #3 above), lodges itself in between the filters, plugging and ripping the filter fibers and lowering the quality of the effluent that is produced.

- The filter tubes that contain the permeate are clogging with a foreign matter of unknown makeup. This material is being sent to the lab for analysis to determine if an easy chemical adjustment or additional cleaning procedure with a different chemical would be effective for cleaning them.

*8 – UV Bulb Units: Over the past 7+ years, the UV Bulb Units have been periodically failing. Each failure of the unit causes a pair of 2 bulbs to fail. Rather than repairing or replacing the units, the bulbs were being replaced as a cost of $800 per failure. Matt and his team have rebuilt one of the two units which has eliminated the failures, and plan to rebuild the second unit during the next period of extended rainfall .

*9 – Supervisory Control and Data Acquisition (SCADA): SCADA is the name of the computer electronics that control and monitor the functioning of the entire process at the Sanitary Plant. The primary control-interface panel broke over four years ago and was not replaced. The remaining computer (Windows XP) reached the end of its life cycle several years ago and periodically crashes. Software and licensing is out of date. In January, Matt, his team, the acting District Administrator and a Board member were involved in replacing and upgrading the SCADA system with current software, licensing, and technology so that the designed redundancy is built back into the system. The control function has been secured behind the recently installed firewall so as to minimize the risk of being hacked.